Automated Thermostat With Stepper Motor (Fan)

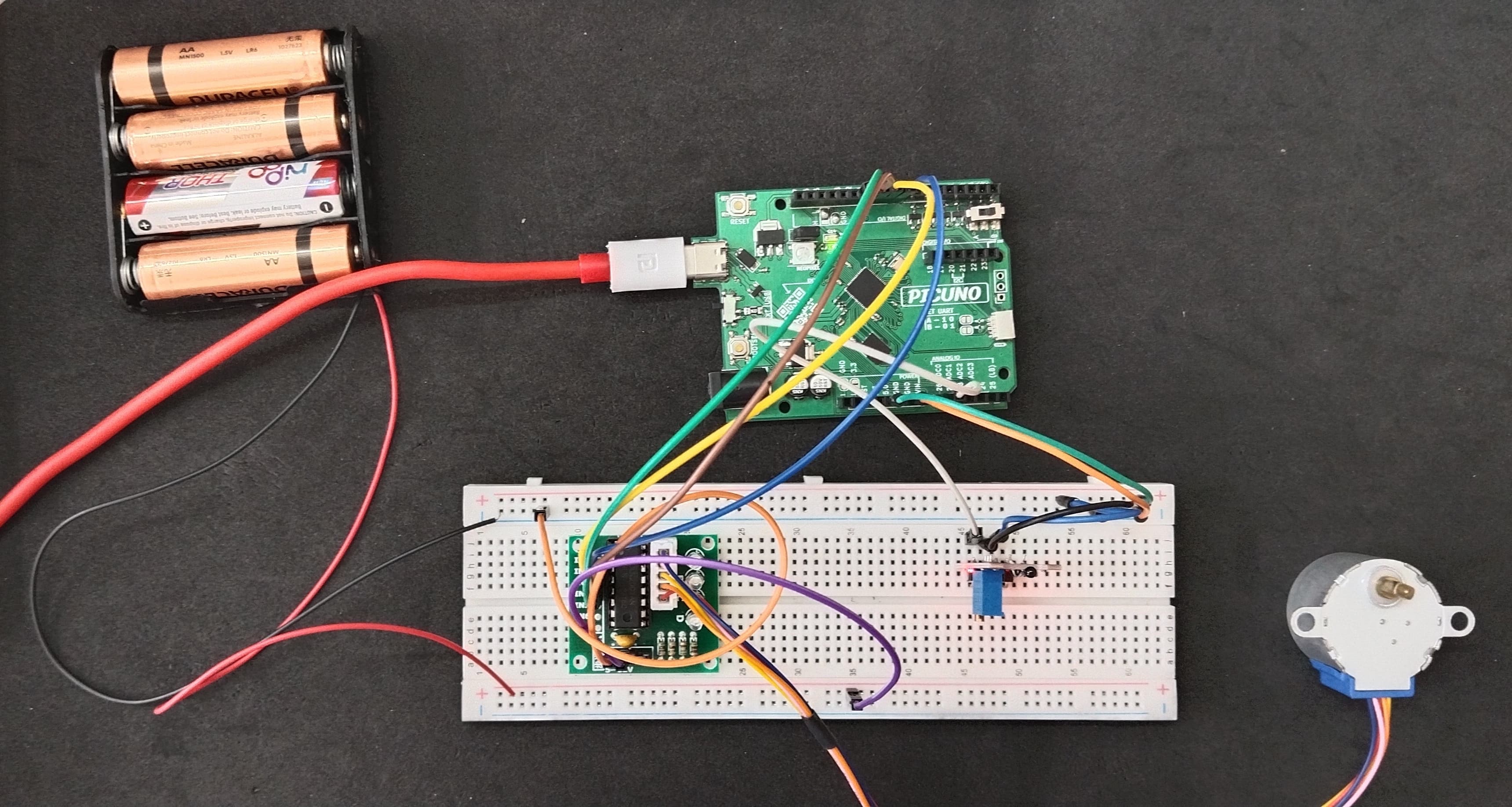

HARDWARE REQUIRED:

- PICUNO Microcontroller board

- 1 × HW-503 Digital Temperature Sensor

- 1 × 5V Stepper Motor

- 1 × ULN2003 Driver Board

- 1 × 4xAA Battery Pack (For external supply)

- Jumper wires

- USB cable

DESCRIPTION:

This project creates a smart thermostat that controls a "fan" made from a stepper motor. The system uses a manual calibration method to get an accurate temperature reading from the sensor. When the ambient temperature rises above a setpoint, the program activates the stepper motor, causing it to spin continuously like a fan. When the temperature drops, the fan automatically turns off. This project demonstrates a real-world closed-loop control system and the importance of calibrating sensors.

NOTE:

The component has an NTC Thermistor module.

Core Component: The black, bead-like component is a special resistor whose resistance changes predictably with temperature.

Key Principle: "NTC" stands for Negative Temperature Coefficient. This simply means as the sensor gets hotter, its electrical resistance gets lower. So the voltage reading also gets lower.

The red circuit board is a "voltage divider." It converts the sensor's changing resistance into a changing voltage. The blue knob allows to set a temperature threshold.

NOTE:

The component has an NTC Thermistor module.

Core Component: The black, bead-like component is a special resistor whose resistance changes predictably with temperature.

Key Principle: "NTC" stands for Negative Temperature Coefficient. This simply means as the sensor gets hotter, its electrical resistance gets lower. So the voltage reading also gets lower.

The red circuit board is a "voltage divider." It converts the sensor's changing resistance into a changing voltage. The blue knob allows to set a temperature threshold.

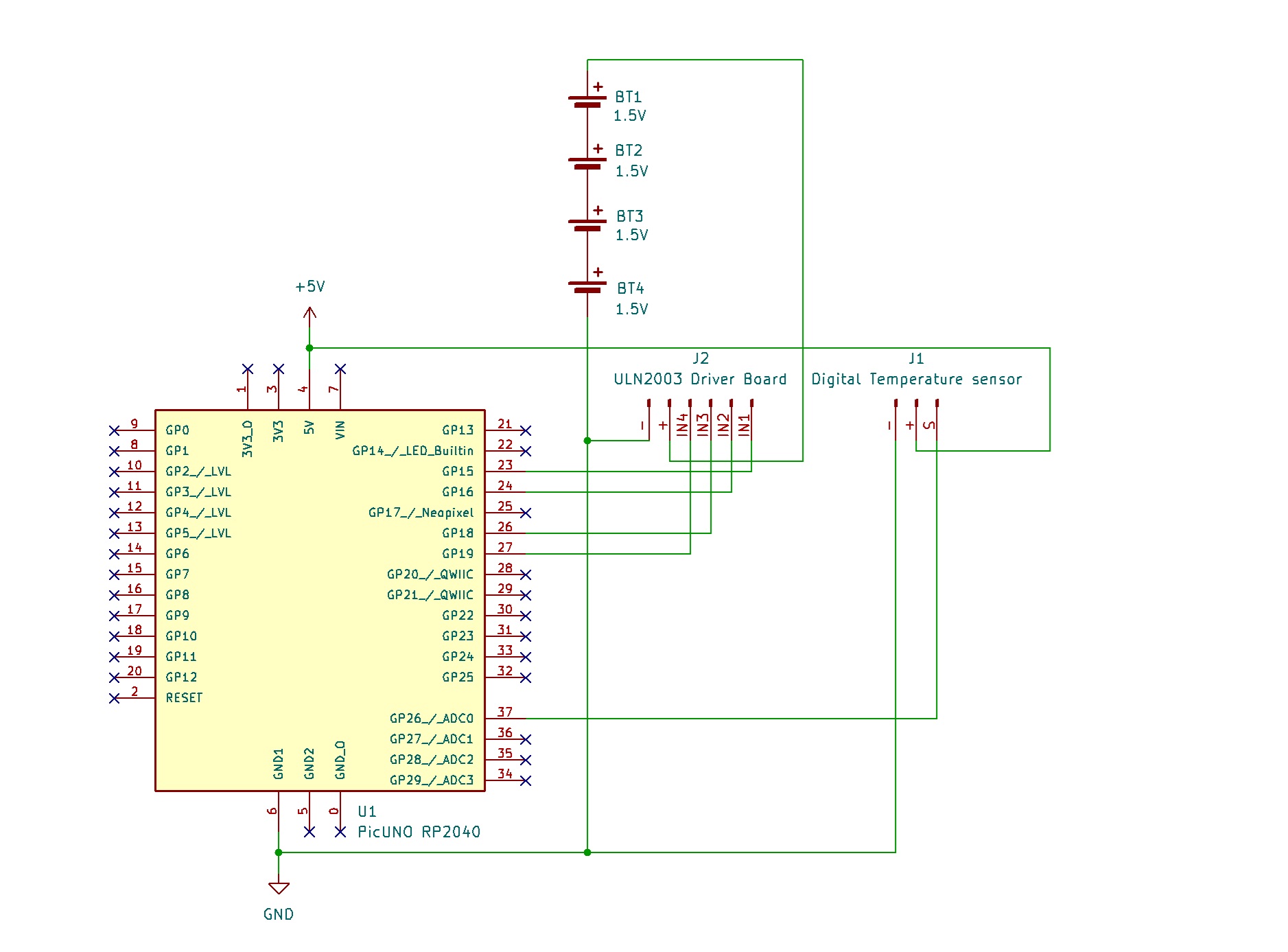

CIRCUIT DIAGRAM:

- Connect IN1, IN2, IN3, IN4 to PICUNO pins GPIO 15, 16, 18, and 19 respectively.

- Connect the driver's + and GND pins to positive terminal of the 4xAA Battery pack and GND respectively.

- Plug the stepper motor's connector into the socket on the driver board.

- Connect the negative terminal of the 4xAA Battery Pack to Common GND on breadboard.

- Connect the GND (G) pin to GND on board.

- Connect the VCC (+) pin to 5V on board.

- Connect the Analog Output (AO) pin to A0 (GPIO 26).

SCHEMATIC:

ULN2003 Driver & Power:

ULN2003 IN1 → PICUNO GPIO 15

ULN2003 IN2 → PICUNO GPIO 16

ULN2003 IN3 → PICUNO GPIO 18

ULN2003 IN4 → PICUNO GPIO 19

ULN2003 Power + Pin → 4xAA Battery Pack (+)

ULN2003 Ground - Pin → GND

Digital Temperature Sensor:

GND (G) pin → GND

VCC (+) pin → 5V

AO pin → A0 (GPIO 26)

Common Ground Connection:

4xAA Battery Pack (-) → PICUNO Board GND

CODE -- C:

const int TEMP_SENSOR_PIN = A0;

const int IN1 = 8;

const int IN2 = 9;

const int IN3 = 10;

const int IN4 = 11;

const float SETPOINT_TEMP = 28.0;

const float HYSTERESIS = 1.0;

const int ROOM_TEMP_READING = 540;

const int WARM_TEMP_READING = 500;

const float ROOM_TEMP_C = 26.0;

const float WARM_TEMP_C = 33.0;

const int step_sequence[8][4] = {

{1, 0, 0, 1}, {1, 0, 0, 0}, {1, 1, 0, 0}, {0, 1, 0, 0},

{0, 1, 1, 0}, {0, 0, 1, 0}, {0, 0, 1, 1}, {0, 0, 0, 1}

};

int motor_pins[4] = {IN1, IN2, IN3, IN4};

int current_motor_step = 0;

// --- State & Timer Variables ---

bool isFanOn = false;

unsigned long lastTempCheckTime = 0;

const long tempCheckInterval = 1000; // Check temperature every 1 second (1000 ms)

void setup() {

Serial.begin(9600);

for (int i = 0; i < 4; i++) {

pinMode(motor_pins[i], OUTPUT);

}

Serial.println("Thermostat Ready. Monitoring temperature...");

}

void loop() {

if (millis() - lastTempCheckTime >= tempCheckInterval) {

// Read and map the temperature value

int currentReading = analogRead(TEMP_SENSOR_PIN);

float temperatureC = map(currentReading, ROOM_TEMP_READING, WARM_TEMP_READING, ROOM_TEMP_C, WARM_TEMP_C);

Serial.print("Current Temp: ");

Serial.print(temperatureC);

Serial.println(" C");

// Check if the fan state needs to change

if (temperatureC > SETPOINT_TEMP) {

if (!isFanOn) {

Serial.println("--> Temperature HIGH. Turning fan ON.");

isFanOn = true;

}

} else if (temperatureC < SETPOINT_TEMP - HYSTERESIS) {

if (isFanOn) {

Serial.println("--> Temperature NORMAL. Turning fan OFF.");

isFanOn = false;

}

}

lastTempCheckTime = millis(); // Reset the timer

}

if (isFanOn) {

current_motor_step++;

if (current_motor_step > 7) {

current_motor_step = 0;

}

for (int i = 0; i < 4; i++) {

digitalWrite(motor_pins[i], step_sequence[current_motor_step][i]);

}

delay(2); // The speed control delay

} else {

for (int i = 0; i < 4; i++) {

digitalWrite(motor_pins[i], LOW);

}

}

}

const int IN1 = 8;

const int IN2 = 9;

const int IN3 = 10;

const int IN4 = 11;

const float SETPOINT_TEMP = 28.0;

const float HYSTERESIS = 1.0;

const int ROOM_TEMP_READING = 540;

const int WARM_TEMP_READING = 500;

const float ROOM_TEMP_C = 26.0;

const float WARM_TEMP_C = 33.0;

const int step_sequence[8][4] = {

{1, 0, 0, 1}, {1, 0, 0, 0}, {1, 1, 0, 0}, {0, 1, 0, 0},

{0, 1, 1, 0}, {0, 0, 1, 0}, {0, 0, 1, 1}, {0, 0, 0, 1}

};

int motor_pins[4] = {IN1, IN2, IN3, IN4};

int current_motor_step = 0;

// --- State & Timer Variables ---

bool isFanOn = false;

unsigned long lastTempCheckTime = 0;

const long tempCheckInterval = 1000; // Check temperature every 1 second (1000 ms)

void setup() {

Serial.begin(9600);

for (int i = 0; i < 4; i++) {

pinMode(motor_pins[i], OUTPUT);

}

Serial.println("Thermostat Ready. Monitoring temperature...");

}

void loop() {

if (millis() - lastTempCheckTime >= tempCheckInterval) {

// Read and map the temperature value

int currentReading = analogRead(TEMP_SENSOR_PIN);

float temperatureC = map(currentReading, ROOM_TEMP_READING, WARM_TEMP_READING, ROOM_TEMP_C, WARM_TEMP_C);

Serial.print("Current Temp: ");

Serial.print(temperatureC);

Serial.println(" C");

// Check if the fan state needs to change

if (temperatureC > SETPOINT_TEMP) {

if (!isFanOn) {

Serial.println("--> Temperature HIGH. Turning fan ON.");

isFanOn = true;

}

} else if (temperatureC < SETPOINT_TEMP - HYSTERESIS) {

if (isFanOn) {

Serial.println("--> Temperature NORMAL. Turning fan OFF.");

isFanOn = false;

}

}

lastTempCheckTime = millis(); // Reset the timer

}

if (isFanOn) {

current_motor_step++;

if (current_motor_step > 7) {

current_motor_step = 0;

}

for (int i = 0; i < 4; i++) {

digitalWrite(motor_pins[i], step_sequence[current_motor_step][i]);

}

delay(2); // The speed control delay

} else {

for (int i = 0; i < 4; i++) {

digitalWrite(motor_pins[i], LOW);

}

}

}

Manual Calibration (map()) - This is the key to getting an accurate reading. The code uses the map() function to convert the raw analogRead() values (e.g., 540-500) into a realistic Celsius range (e.g., 26-33°C) based on your real-world testing.

step_sequence array - This array holds the 8 specific ON/OFF patterns for the motor's four coils. Cycling through them creates smooth rotation.

Dedicated Rotation Loop - When the temperature is high, the code enters a while loop that focuses only on running the motor logic with a delay(2), ensuring it has the perfect timing to spin without getting stuck.

step_sequence array - This array holds the 8 specific ON/OFF patterns for the motor's four coils. Cycling through them creates smooth rotation.

Dedicated Rotation Loop - When the temperature is high, the code enters a while loop that focuses only on running the motor logic with a delay(2), ensuring it has the perfect timing to spin without getting stuck.

CODE -- PYTHON:

from machine import Pin, ADC

from time import sleep_ms

TEMP_SENSOR_PIN = 26

motor_pins = [Pin(p, Pin.OUT) for p in [8, 9, 10, 11]]

SETPOINT_TEMP = 28.0

HYSTERESIS = 1.0

ROOM_TEMP_READING = 34000

WARM_TEMP_READING = 30000

ROOM_TEMP_C = 26.0

WARM_TEMP_C = 33.0

step_sequence = [[1,0,0,1],[1,0,0,0],[1,1,0,0],[0,1,0,0],[0,1,1,0],[0,0,1,0],[0,0,1,1],[1,0,0,1]]

current_motor_step = 0

temp_sensor = ADC(Pin(TEMP_SENSOR_PIN))

print("Thermostat Ready (Calibrated).")

# --- Helper Function ---

def map_value(x, in_min, in_max, out_min, out_max):

return (x - in_min) * (out_max - out_min) / (in_max - in_min) + out_min

# --- Main Loop ---

while True:

current_reading = temp_sensor.read_u16()

temperatureC = map_value(current_reading, ROOM_TEMP_READING, WARM_TEMP_READING, ROOM_TEMP_C, WARM_TEMP_C)

print(f"Current Temp: {temperatureC:.2f} C")

if temperatureC > SETPOINT_TEMP:

print("--> Temperature HIGH. Fan is ON.")

while temperatureC > SETPOINT_TEMP - HYSTERESIS:

current_motor_step = (current_motor_step + 1) % 8

for i in range(4):

motor_pins[i].value(step_sequence[current_motor_step][i])

sleep_ms(2)

# Re-check temperature to see if we should stop

current_reading = temp_sensor.read_u16()

temperatureC = map_value(current_reading, ROOM_TEMP_READING, WARM_TEMP_READING, ROOM_TEMP_C, WARM_TEMP_C)

print("--> Temperature NORMAL. Turning fan OFF.")

for pin in motor_pins:

pin.value(0) # De-energize motor

sleep_ms(1000)

from time import sleep_ms

TEMP_SENSOR_PIN = 26

motor_pins = [Pin(p, Pin.OUT) for p in [8, 9, 10, 11]]

SETPOINT_TEMP = 28.0

HYSTERESIS = 1.0

ROOM_TEMP_READING = 34000

WARM_TEMP_READING = 30000

ROOM_TEMP_C = 26.0

WARM_TEMP_C = 33.0

step_sequence = [[1,0,0,1],[1,0,0,0],[1,1,0,0],[0,1,0,0],[0,1,1,0],[0,0,1,0],[0,0,1,1],[1,0,0,1]]

current_motor_step = 0

temp_sensor = ADC(Pin(TEMP_SENSOR_PIN))

print("Thermostat Ready (Calibrated).")

# --- Helper Function ---

def map_value(x, in_min, in_max, out_min, out_max):

return (x - in_min) * (out_max - out_min) / (in_max - in_min) + out_min

# --- Main Loop ---

while True:

current_reading = temp_sensor.read_u16()

temperatureC = map_value(current_reading, ROOM_TEMP_READING, WARM_TEMP_READING, ROOM_TEMP_C, WARM_TEMP_C)

print(f"Current Temp: {temperatureC:.2f} C")

if temperatureC > SETPOINT_TEMP:

print("--> Temperature HIGH. Fan is ON.")

while temperatureC > SETPOINT_TEMP - HYSTERESIS:

current_motor_step = (current_motor_step + 1) % 8

for i in range(4):

motor_pins[i].value(step_sequence[current_motor_step][i])

sleep_ms(2)

# Re-check temperature to see if we should stop

current_reading = temp_sensor.read_u16()

temperatureC = map_value(current_reading, ROOM_TEMP_READING, WARM_TEMP_READING, ROOM_TEMP_C, WARM_TEMP_C)

print("--> Temperature NORMAL. Turning fan OFF.")

for pin in motor_pins:

pin.value(0) # De-energize motor

sleep_ms(1000)

Manual Calibration (map_value) - The code uses a custom map_value function to convert the raw 16-bit ADC values (e.g., 34000-30000) into a Celsius range based on your real-world calibration, making the reading accurate for your specific sensor.

step_sequence list - Holds the 8 electrical patterns that are sent to the four motor pins in sequence to create rotation.

Dedicated Rotation Loop - Just like the Arduino version, when the fan needs to be on, the code enters a focused while loop that does nothing but step the motor with a 2ms delay, ensuring smooth, uninterrupted rotation.

step_sequence list - Holds the 8 electrical patterns that are sent to the four motor pins in sequence to create rotation.

Dedicated Rotation Loop - Just like the Arduino version, when the fan needs to be on, the code enters a focused while loop that does nothing but step the motor with a 2ms delay, ensuring smooth, uninterrupted rotation.