Joystick Controlled Pan And Tilt Servo Arm

HARDWARE REQUIRED:

- PICUNO Microcontroller board

- 2 × SG90 Servo Motor

- 1 × HW-504 Joystick Module

- 1 × 4xAA Battery Pack (for external power supply)

- Jumper wires

- USB cable

DESCRIPTION:

This project creates a 2-axis Pan and Tilt mechanism controlled in real-time by a joystick. Two servos work together to control the horizontal (pan) and vertical (tilt) movement. The joystick provides intuitive, two-dimensional Analog input, which is translated directly into servo positions. This project serves as a foundational building block for robotic camera gimbals, sensor turrets, or articulated arms.

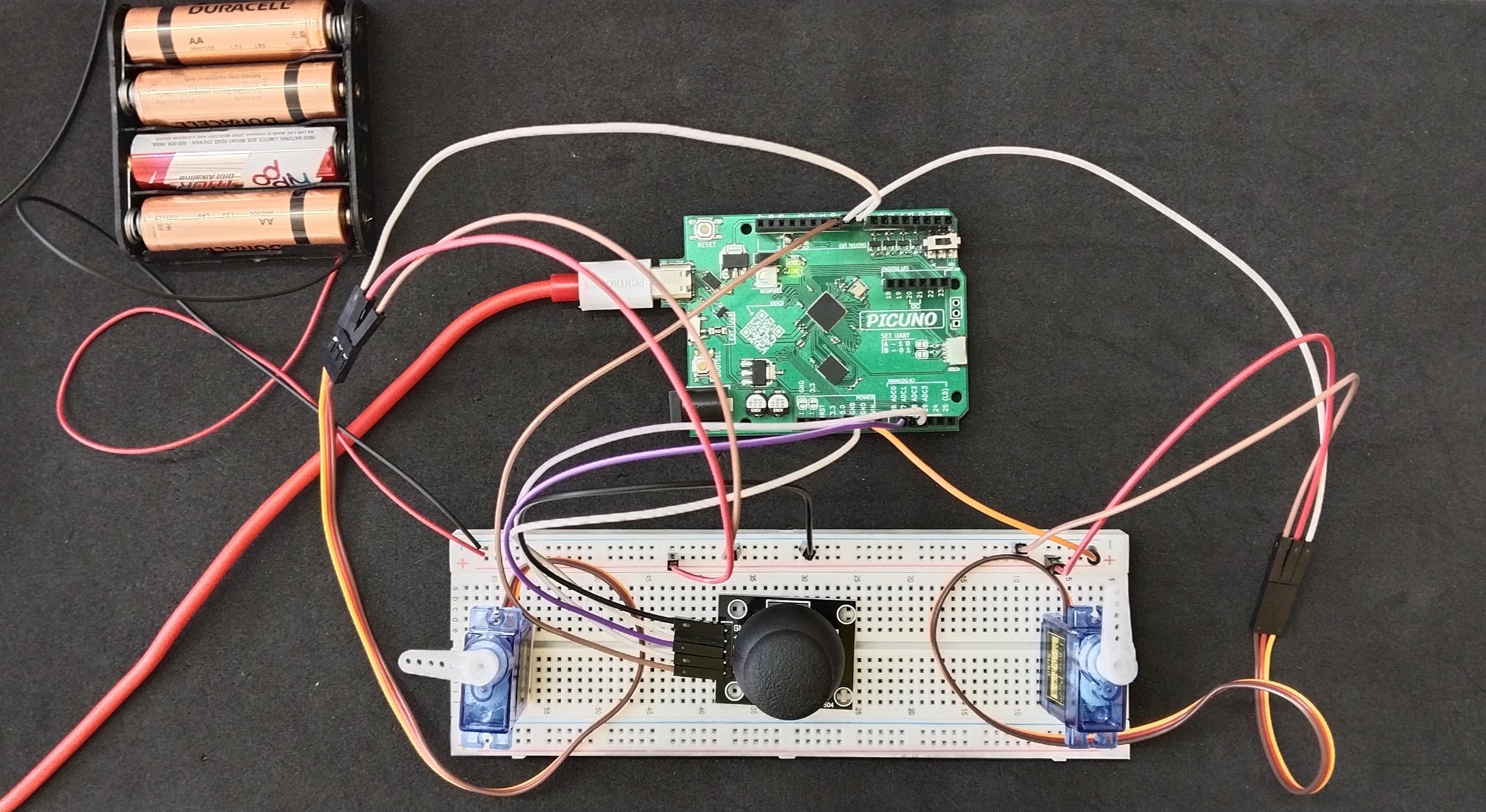

CIRCUIT DIAGRAM:

- Connect the both Servo's VCC (Red) pin to the Positive (+) terminal of the 4xAA Battery Pack.

- Connect the both Servo's GND (Brown) pin to GND.

- Connect the Pan Servo's Signal (Yellow) pin to GPIO 8.

- Connect the Tilt Servo's Signal (Yellow) pin to GPIO 9.

- JOYSTICK MODULE:

- Connect the VCC pin to 5V pin on the board.

- Connect the GND pin to GND pin on board.

- Connect the VRx pin to Analog Pin A0 (GPIO 26).

- Connect the VRy pin to Analog Pin A1 (GPIO 27).

- Connect the Negative (-) terminal of the 4xAA Battery Pack to GND pin on the PICUNO board to create a common ground connection.

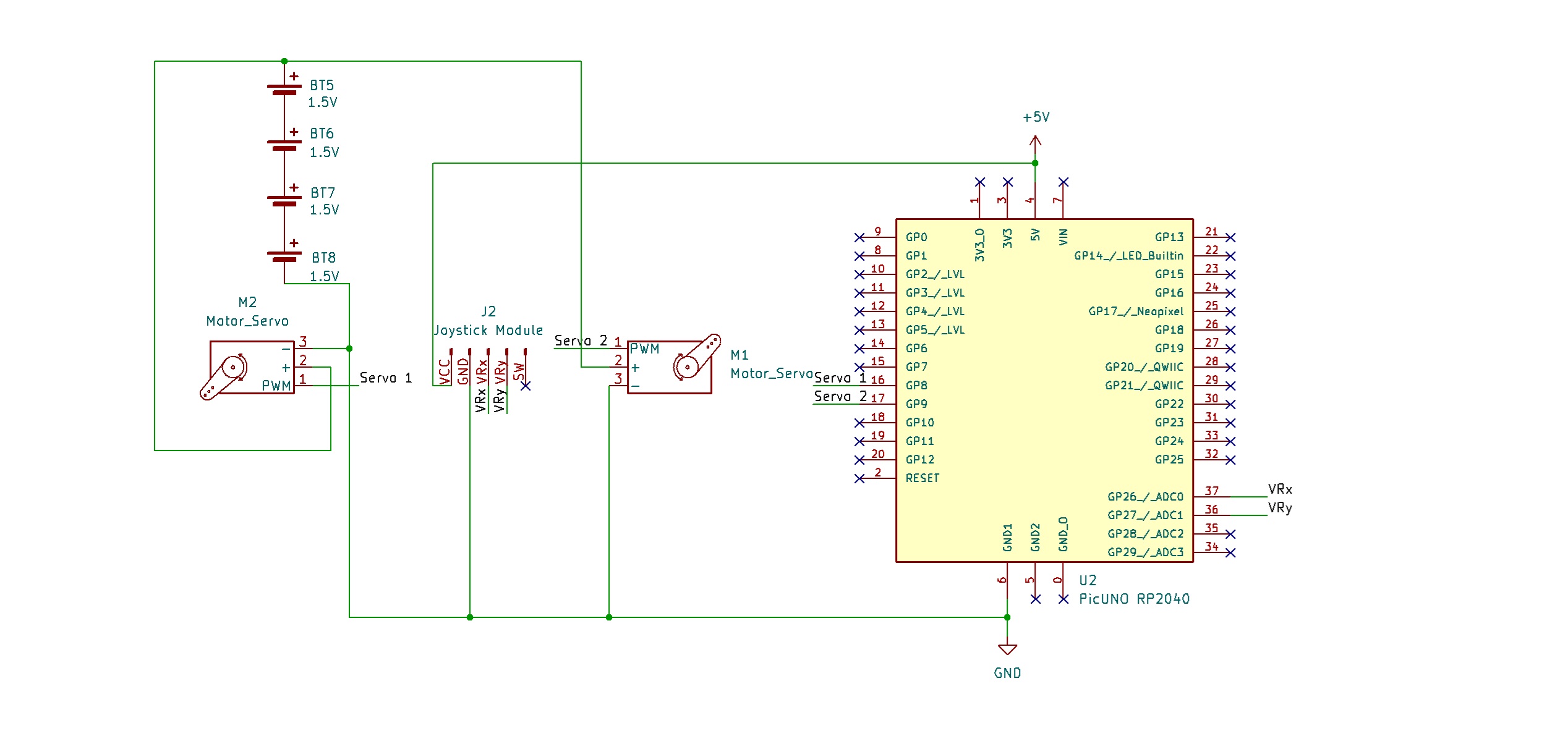

SCHEMATIC:

Pan Servo Motor:

VCC (Red Wire) → 4xAA Battery Pack (+)

GND (Brown Wire) → GND

Signal (Yellow Wire) → GPIO 8

Tilt Servo Motor:

VCC (Red Wire) → 4xAA Battery Pack (+)

GND (Brown Wire) → GND

Signal (Yellow Wire) → GPIO 9

Joystick Module:

VCC → 5V

GND → GND

VRx → A0

VRy → A1

Common Ground Connection:

4xAA Battery Pack (-) → PICUNO Board GND

CODE -- C:

#include <Servo.h>

#define JOY_X_PIN A0

#define JOY_Y_PIN A1

#define PAN_SERVO_PIN 8

#define TILT_SERVO_PIN 9

Servo panServo;

Servo tiltServo;

void setup() {

Serial.begin(9600);

Serial.println("Pan/Tilt Ready");

panServo.attach(PAN_SERVO_PIN, 500, 2500);

tiltServo.attach(TILT_SERVO_PIN, 500, 2500);

panServo.write(90);

tiltServo.write(90);

delay(1000);

}

void loop() {

int joyX = analogRead(JOY_X_PIN);

int joyY = analogRead(JOY_Y_PIN);

int panAngle = map(joyX, 0, 1023, 0, 180);

int tiltAngle = map(joyY, 0, 1023, 180, 0); // Invert tilt axis for intuitive control

// Write angles to servos

panServo.write(panAngle);

tiltServo.write(tiltAngle);

// Display information on the Serial Monitor

Serial.print("Pan: ");

Serial.print(panAngle);

Serial.print(" Tilt: ");

Serial.println(tiltAngle);

delay(30);

}

#define JOY_X_PIN A0

#define JOY_Y_PIN A1

#define PAN_SERVO_PIN 8

#define TILT_SERVO_PIN 9

Servo panServo;

Servo tiltServo;

void setup() {

Serial.begin(9600);

Serial.println("Pan/Tilt Ready");

panServo.attach(PAN_SERVO_PIN, 500, 2500);

tiltServo.attach(TILT_SERVO_PIN, 500, 2500);

panServo.write(90);

tiltServo.write(90);

delay(1000);

}

void loop() {

int joyX = analogRead(JOY_X_PIN);

int joyY = analogRead(JOY_Y_PIN);

int panAngle = map(joyX, 0, 1023, 0, 180);

int tiltAngle = map(joyY, 0, 1023, 180, 0); // Invert tilt axis for intuitive control

// Write angles to servos

panServo.write(panAngle);

tiltServo.write(tiltAngle);

// Display information on the Serial Monitor

Serial.print("Pan: ");

Serial.print(panAngle);

Serial.print(" Tilt: ");

Serial.println(tiltAngle);

delay(30);

}

analogRead(PIN) - This reads the voltage from an Analog pin (connected to the joystick) and converts it into a number between 0 and 1023.

panServo.write(angle) - This is the final command that tells the servo motor to move to the position specified by the angle variable.

panServo.attach(..., 500, 2500) - Both servos are attached using the custom pulse width range to ensure they can achieve their full 180-degree motion.

map() - Scales the joystick's 0-1023 input range to the servo's 0-180 degree output range.

panServo.write(angle) - This is the final command that tells the servo motor to move to the position specified by the angle variable.

panServo.attach(..., 500, 2500) - Both servos are attached using the custom pulse width range to ensure they can achieve their full 180-degree motion.

map() - Scales the joystick's 0-1023 input range to the servo's 0-180 degree output range.

CODE -- PYTHON:

from machine import Pin, ADC, PWM

from time import sleep

joy_x_adc = ADC(Pin(26)) # A0

joy_y_adc = ADC(Pin(27)) # A1

pan_pwm = PWM(Pin(8))

tilt_pwm = PWM(Pin(9))

pan_pwm.freq(50)

tilt_pwm.freq(50)

def map_value(x, in_min, in_max, out_min, out_max):

return (x - in_min) * (out_max - out_min) // (in_max - in_min) + out_min

def set_servo_angle(pwm_obj, angle):

angle = max(0, min(180, angle)) # Constrain angle

duty = map_value(angle, 0, 180, 1350, 8350)

pwm_obj.duty_u16(duty)

print("Pan/Tilt Ready")

set_servo_angle(pan_pwm, 90)

set_servo_angle(tilt_pwm, 90)

sleep(1)

# --- Main Loop ---

while True:

joy_x = joy_x_adc.read_u16()

joy_y = joy_y_adc.read_u16()

pan_angle = map_value(joy_x, 0, 65535, 0, 180)

tilt_angle = map_value(joy_y, 0, 65535, 180, 0) # Inverted for intuitive control

# Set servo positions

set_servo_angle(pan_pwm, pan_angle)

set_servo_angle(tilt_pwm, tilt_angle)

print(f"Pan: {pan_angle}, Tilt: {tilt_angle}")

sleep(0.03)

from time import sleep

joy_x_adc = ADC(Pin(26)) # A0

joy_y_adc = ADC(Pin(27)) # A1

pan_pwm = PWM(Pin(8))

tilt_pwm = PWM(Pin(9))

pan_pwm.freq(50)

tilt_pwm.freq(50)

def map_value(x, in_min, in_max, out_min, out_max):

return (x - in_min) * (out_max - out_min) // (in_max - in_min) + out_min

def set_servo_angle(pwm_obj, angle):

angle = max(0, min(180, angle)) # Constrain angle

duty = map_value(angle, 0, 180, 1350, 8350)

pwm_obj.duty_u16(duty)

print("Pan/Tilt Ready")

set_servo_angle(pan_pwm, 90)

set_servo_angle(tilt_pwm, 90)

sleep(1)

# --- Main Loop ---

while True:

joy_x = joy_x_adc.read_u16()

joy_y = joy_y_adc.read_u16()

pan_angle = map_value(joy_x, 0, 65535, 0, 180)

tilt_angle = map_value(joy_y, 0, 65535, 180, 0) # Inverted for intuitive control

# Set servo positions

set_servo_angle(pan_pwm, pan_angle)

set_servo_angle(tilt_pwm, tilt_angle)

print(f"Pan: {pan_angle}, Tilt: {tilt_angle}")

sleep(0.03)

ADC and PWM Objects - These are created to handle Analog input from the joystick and generate the specific PWM signal required by the servos.

set_servo_angle() - A helper function used to handle the logic for setting a servo's angle, which makes the main code cleaner.

read_u16() - Reads the joystick's position as a high-resolution number from 0 to 65535.

print(f"...") - Uses an f-string to easily format and send the live angle data to your Thonny IDE's Shell for feedback.

set_servo_angle() - A helper function used to handle the logic for setting a servo's angle, which makes the main code cleaner.

read_u16() - Reads the joystick's position as a high-resolution number from 0 to 65535.

print(f"...") - Uses an f-string to easily format and send the live angle data to your Thonny IDE's Shell for feedback.