Stepper Motor Speed And Direction Control

HARDWARE REQUIRED:

- PICUNO Microcontroller board

- 1 × 5V Stepper Motor

- 1 × ULN2003 Driver Board

- 1 × 10kΩ Potentiometer

- 1 × Push Button

- 1 × 10kΩ Resistor (Pull-down)

- Jumper wires

- USB cable

- 9V Battery with a snap connector (to power the board via the DC Jack)

DESCRIPTION:

This project provides precise real-time control over a 5V stepper motor. A potentiometer acts as a speed dial, allowing you to vary the motor's rotation speed smoothly. A separate push button is used to instantly toggle the motor's direction between clockwise and counter-clockwise. The code drives the motor using a half-step sequence, which provides smoother motion and double the resolution compared to full-stepping. This setup is a fundamental building block for robotics, CNC machines, and any project requiring precise positional control.

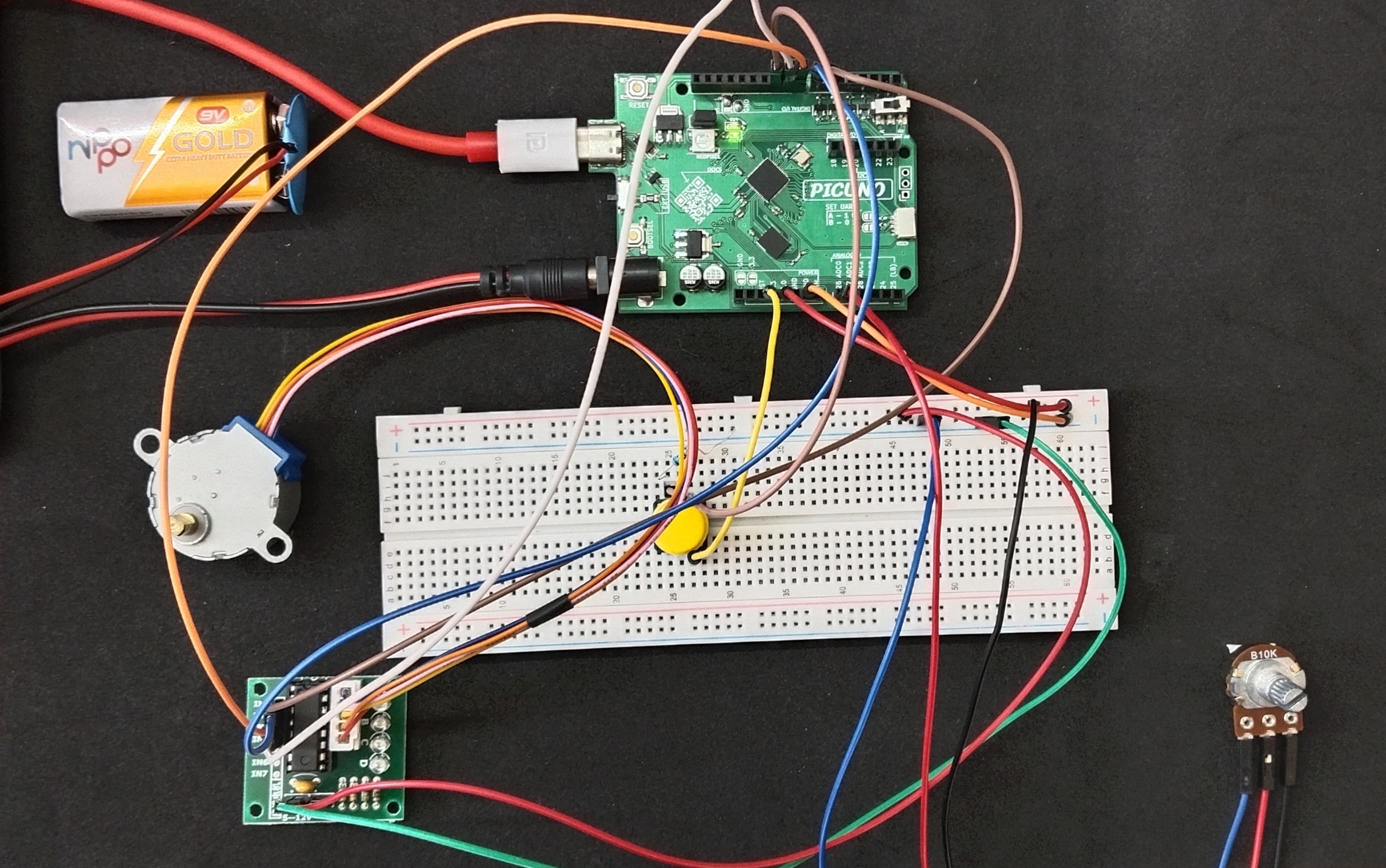

CIRCUIT DIAGRAM:

- Connect the Potentiometer centre pin to A0 (GPIO 26), and the outer pins to 3.3V and GND.

- Connect one leg of the Push Button to 3.3V.

- Connect other leg of the Push Button to GPIO 10 and connect a pull-down resistor of 10kΩ from GPIO 10 to GND.

- ULN2003 Driver Board:

- Connect IN1, IN2, IN3, IN4 to PICUNO pins GPIO 6, 7, 8, and 9 respectively.

- Connect the driver's + and GND pins to 5V and GND.

- Plug the stepper motor's connector into the socket on the driver board.

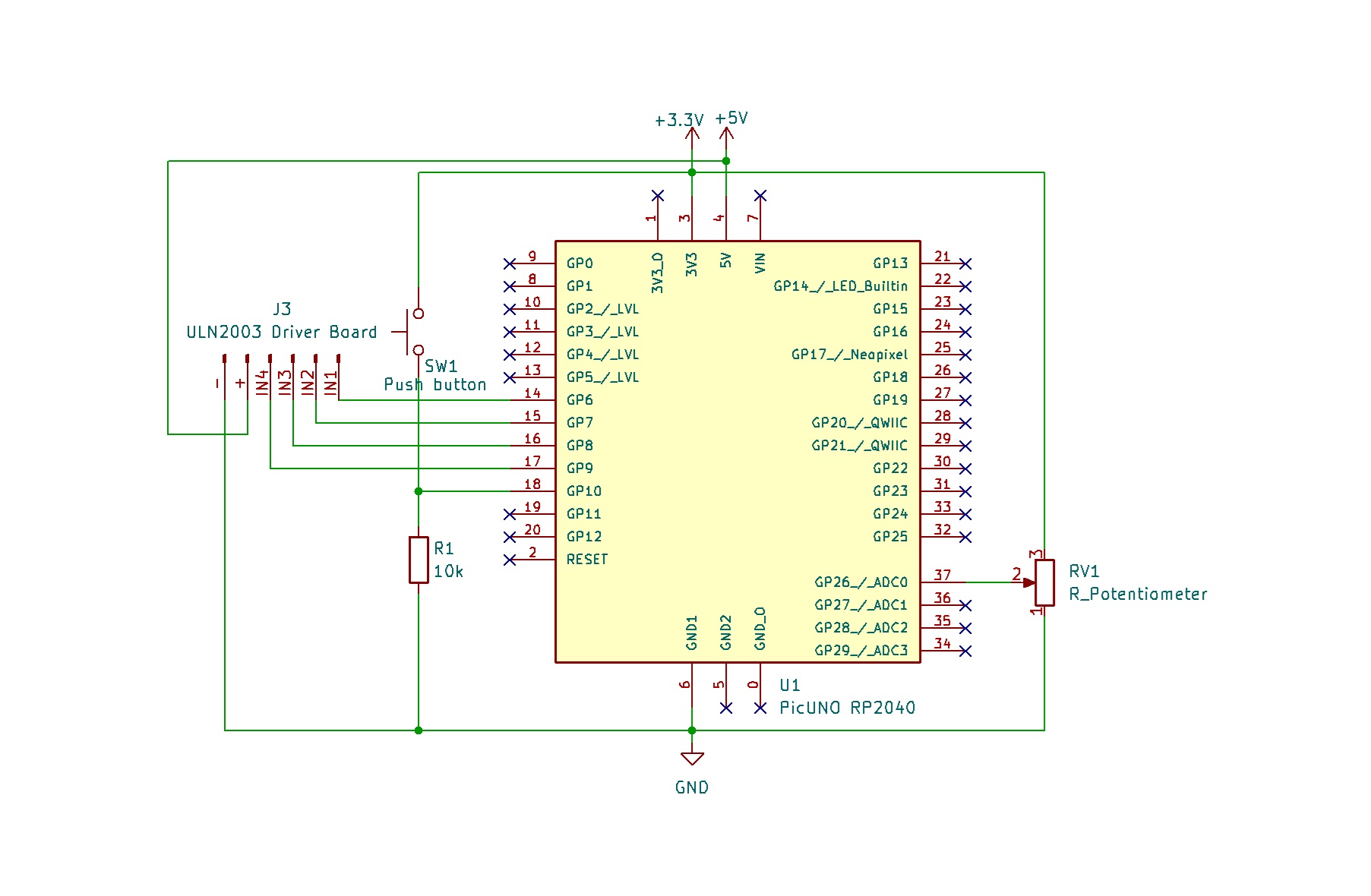

SCHEMATIC:

Potentiometer Centre Pin → A0 (GPIO 26)

Potentiometer Rightmost Pin → 3.3V

Potentiometer Leftmost Pin → GND

Push Button one side → 3.3V

Push Button other side → GPIO 10 → 10kΩ Resistor → GND

ULN2003 Driver & Power:

ULN2003 IN1 → PICUNO GPIO 6

ULN2003 IN2 → PICUNO GPIO 7

ULN2003 IN3 → PICUNO GPIO 8

ULN2003 IN4 → PICUNO GPIO 9

ULN2003 Power + Pin → 5V

ULN2003 Ground - Pin → GND

CODE -- C:

const int IN1 = 6;

const int IN2 = 7;

const int IN3 = 8;

const int IN4 = 9;

const int motorPins[] = {IN1, IN2, IN3, IN4};

const int potPin = A0;

const int buttonPin = 10;

// Stepper sequence (half-step mode)

const int step_sequence[8][4] = {

{1,0,0,0}, {1,1,0,0}, {0,1,0,0}, {0,1,1,0},

{0,0,1,0}, {0,0,1,1}, {0,0,0,1}, {1,0,0,1}

};

int current_dir = 1; // 1 = forward, -1 = backward

int last_btn_state = LOW;

int step_index = 0;

void move_step(int index) {

for (int i = 0; i < 4; i++) {

digitalWrite(motorPins[i], step_sequence[index][i]);

}

}

void setup() {

for (int i = 0; i < 4; i++) {

pinMode(motorPins[i], OUTPUT);

}

pinMode(buttonPin, INPUT_PULLUP);

}

void loop() {

// Check button press to toggle direction

int btn_state = digitalRead(buttonPin);

if (btn_state == LOW && last_btn_state == HIGH) {

current_dir *= -1;

delay(50); // debounce delay

}

last_btn_state = btn_state;

int pot_val = analogRead(potPin);

// map() is used to convert the 0-1023 pot range to a 2000-20000 microsecond delay range

long delay_us = map(pot_val, 0, 1023, 20000, 2000);

move_step(step_index);

delayMicroseconds(delay_us);

step_index = (step_index + current_dir + 8) % 8; // The +8 ensures the result is always positive

}

const int IN2 = 7;

const int IN3 = 8;

const int IN4 = 9;

const int motorPins[] = {IN1, IN2, IN3, IN4};

const int potPin = A0;

const int buttonPin = 10;

// Stepper sequence (half-step mode)

const int step_sequence[8][4] = {

{1,0,0,0}, {1,1,0,0}, {0,1,0,0}, {0,1,1,0},

{0,0,1,0}, {0,0,1,1}, {0,0,0,1}, {1,0,0,1}

};

int current_dir = 1; // 1 = forward, -1 = backward

int last_btn_state = LOW;

int step_index = 0;

void move_step(int index) {

for (int i = 0; i < 4; i++) {

digitalWrite(motorPins[i], step_sequence[index][i]);

}

}

void setup() {

for (int i = 0; i < 4; i++) {

pinMode(motorPins[i], OUTPUT);

}

pinMode(buttonPin, INPUT_PULLUP);

}

void loop() {

// Check button press to toggle direction

int btn_state = digitalRead(buttonPin);

if (btn_state == LOW && last_btn_state == HIGH) {

current_dir *= -1;

delay(50); // debounce delay

}

last_btn_state = btn_state;

int pot_val = analogRead(potPin);

// map() is used to convert the 0-1023 pot range to a 2000-20000 microsecond delay range

long delay_us = map(pot_val, 0, 1023, 20000, 2000);

move_step(step_index);

delayMicroseconds(delay_us);

step_index = (step_index + current_dir + 8) % 8; // The +8 ensures the result is always positive

}

step_sequence - A 2D array that holds the 8 distinct ON/OFF patterns for the four motor coils to achieve a half-step rotation.

move_step() - A function that takes a step number (0-7) and applies the corresponding pattern to the motor pins.

map(pot_val, 0, 1023, 20000, 2000) - This line reads the potentiometer value (0-1023) and scales it to a delay in microseconds. Note that the output range is reversed (20000 to 2000), so a low pot value gives a long delay (slow speed) and a high pot value gives a short delay (fast speed).

step_index = (step_index + current_dir + 8) % 8 - This line advances the motor to the next step in the sequence. It adds 1 or -1 depending on the direction and uses the modulo (%) operator to make sure the index wraps around (from 7 to 0, or 0 to 7), creating continuous rotation.

move_step() - A function that takes a step number (0-7) and applies the corresponding pattern to the motor pins.

map(pot_val, 0, 1023, 20000, 2000) - This line reads the potentiometer value (0-1023) and scales it to a delay in microseconds. Note that the output range is reversed (20000 to 2000), so a low pot value gives a long delay (slow speed) and a high pot value gives a short delay (fast speed).

step_index = (step_index + current_dir + 8) % 8 - This line advances the motor to the next step in the sequence. It adds 1 or -1 depending on the direction and uses the modulo (%) operator to make sure the index wraps around (from 7 to 0, or 0 to 7), creating continuous rotation.

CODE -- PYTHON:

from machine import Pin, ADC

from time import sleep

# Stepper pins (IN1-IN4)

IN1 = Pin(6, Pin.OUT)

IN2 = Pin(7, Pin.OUT)

IN3 = Pin(8, Pin.OUT)

IN4 = Pin(9, Pin.OUT)

# Potentiometer (speed control)

pot = ADC(26) # A0

# Direction button

button = Pin(10, Pin.IN)

# Stepper sequence (half-step mode)

step_sequence = [

[1,0,0,0],

[1,1,0,0],

[0,1,0,0],

[0,1,1,0],

[0,0,1,0],

[0,0,1,1],

[0,0,0,1],

[1,0,0,1],

]

current_dir = 1 # 1 = forward, -1 = backward

last_btn = 0

step_index = 0

def move_step(index):

pins = step_sequence[index]

IN1.value(pins[0])

IN2.value(pins[1])

IN3.value(pins[2])

IN4.value(pins[3])

while True:

# Check button press to toggle direction

if button.value() == 1 and last_btn == 0:

current_dir *= -1

sleep(0.2) # debounce delay

last_btn = button.value()

# Read potentiometer value (0–65535) → delay

pot_val = pot.read_u16()

delay = 0.002 + (1 - pot_val / 65535) * 0.018 # range: 2ms to 20ms

move_step(step_index)

sleep(delay)

step_index = (step_index + current_dir) % 8

from time import sleep

# Stepper pins (IN1-IN4)

IN1 = Pin(6, Pin.OUT)

IN2 = Pin(7, Pin.OUT)

IN3 = Pin(8, Pin.OUT)

IN4 = Pin(9, Pin.OUT)

# Potentiometer (speed control)

pot = ADC(26) # A0

# Direction button

button = Pin(10, Pin.IN)

# Stepper sequence (half-step mode)

step_sequence = [

[1,0,0,0],

[1,1,0,0],

[0,1,0,0],

[0,1,1,0],

[0,0,1,0],

[0,0,1,1],

[0,0,0,1],

[1,0,0,1],

]

current_dir = 1 # 1 = forward, -1 = backward

last_btn = 0

step_index = 0

def move_step(index):

pins = step_sequence[index]

IN1.value(pins[0])

IN2.value(pins[1])

IN3.value(pins[2])

IN4.value(pins[3])

while True:

# Check button press to toggle direction

if button.value() == 1 and last_btn == 0:

current_dir *= -1

sleep(0.2) # debounce delay

last_btn = button.value()

# Read potentiometer value (0–65535) → delay

pot_val = pot.read_u16()

delay = 0.002 + (1 - pot_val / 65535) * 0.018 # range: 2ms to 20ms

move_step(step_index)

sleep(delay)

step_index = (step_index + current_dir) % 8

step_sequence - A list of lists defining the 8 patterns for the half-step sequence. 1 is ON, 0 is OFF.

move_step() - This function simplifies the main loop by setting the four motor pins based on the current step in the sequence.

current_dir *= -1 - This line cleverly toggles the direction. It multiplies the current_dir variable by -1, flipping it between 1 (forward) and -1 (backward).

delay = 0.002 + (1 - (pot_val / 65535)) * 0.018 - This line maps the 16-bit potentiometer value to a delay between steps. The (1 - ...) part inverts the logic, so a higher pot reading results in a shorter delay and faster speed.

step_index = (step_index + current_dir) % 8 - This is the core of the movement. It advances the index forward or backward through the step_sequence and uses the modulo (%) operator to wrap the index back to 0 when it goes past 7 (or back to 7 from 0), ensuring continuous rotation.

move_step() - This function simplifies the main loop by setting the four motor pins based on the current step in the sequence.

current_dir *= -1 - This line cleverly toggles the direction. It multiplies the current_dir variable by -1, flipping it between 1 (forward) and -1 (backward).

delay = 0.002 + (1 - (pot_val / 65535)) * 0.018 - This line maps the 16-bit potentiometer value to a delay between steps. The (1 - ...) part inverts the logic, so a higher pot reading results in a shorter delay and faster speed.

step_index = (step_index + current_dir) % 8 - This is the core of the movement. It advances the index forward or backward through the step_sequence and uses the modulo (%) operator to wrap the index back to 0 when it goes past 7 (or back to 7 from 0), ensuring continuous rotation.