Motor Speed Tachometer

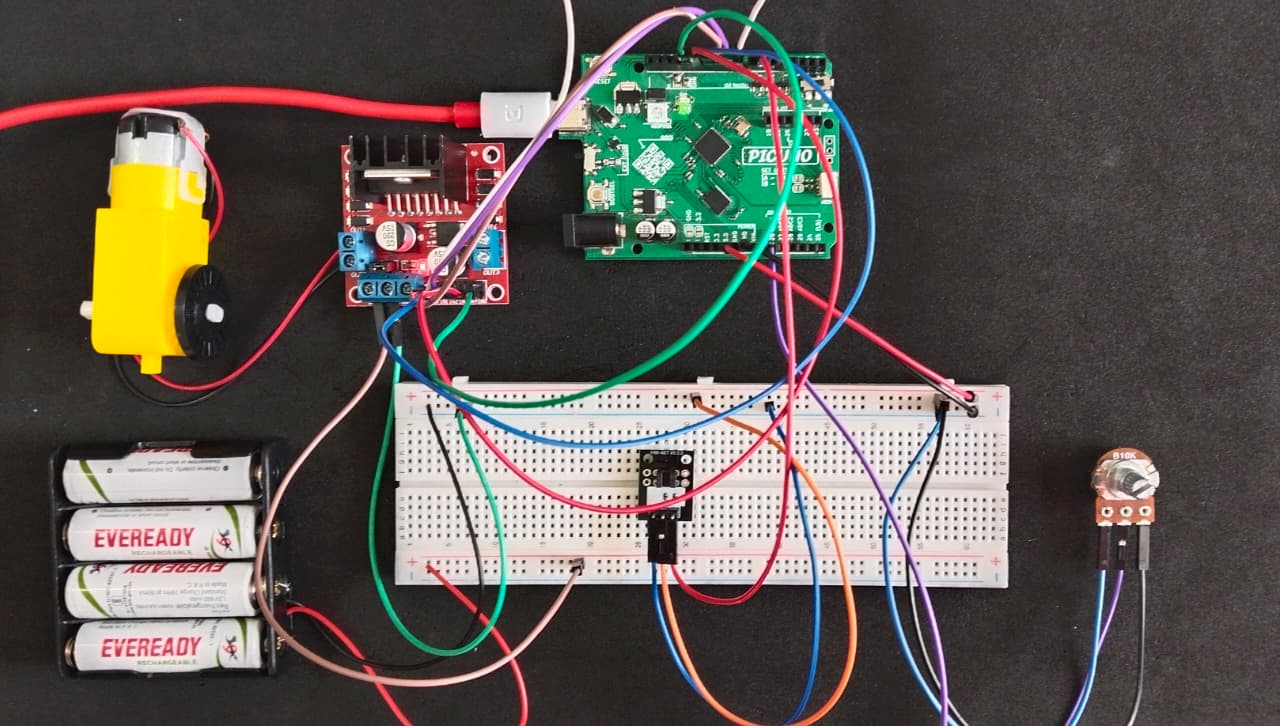

HARDWARE REQUIRED:

- PICUNO Microcontroller board

- 1 × DC Motor with encoder disk (20 shafts)

- 1 × 298N Motor Driver

- 1 × 10kΩ Potentiometer

- 1 × Light Blocking sensor

- 1 × 4xAA Battery pack (with fresh or rechargeable batteries)

- Jumper wires

- USB cable

DESCRIPTION:

This project creates a functional tachometer, a device that measures the rotational speed of a motor in Revolutions Per Minute (RPM).

A small disk with one or more slots is attached to the motor shaft. This disk spins through the Light Blocking Sensor's slot. Each time a slot in the disk passes through the sensor, the infrared beam is unblocked, generating a digital pulse. The PICUNO uses hardware interrupts for precise pulse counting. It counts the number of pulses over a set period, calculates the RPM, and prints the result to the Serial Monitor in real-time. A potentiometer is used as a throttle to control the motor's speed, allowing you to instantly see how the RPM changes.

A small disk with one or more slots is attached to the motor shaft. This disk spins through the Light Blocking Sensor's slot. Each time a slot in the disk passes through the sensor, the infrared beam is unblocked, generating a digital pulse. The PICUNO uses hardware interrupts for precise pulse counting. It counts the number of pulses over a set period, calculates the RPM, and prints the result to the Serial Monitor in real-time. A potentiometer is used as a throttle to control the motor's speed, allowing you to instantly see how the RPM changes.

CIRCUIT DIAGRAM:

- OUT1 & OUT2: Connect these two screw terminals to the outputs for the DC Motor. Connect the two wires from one DC motor here.

- Connect the positive terminal (+) of the 4xAA battery pack to the 12V screw terminal.

- Connect the negative terminal (-) of the 4xAA battery pack to the GND screw terminal.

- Also connect the GND terminal on the L298N to a GND pin on the microcontroller to create a common ground.

- Connect the IN1 pin (Left motor) to GPIO 8.

- Connect the IN2 pin (Left motor) to GPIO 9.

- Connect the ENA pin (Left motor speed) to GPIO 10.

- Connect the IN1 pin (Right motor) to GPIO 11.

- Connect the IN2 pin (Right motor) to GPIO 12.

- Connect the ENB pin (Right motor speed) to GPIO 13.

NOTE: Remove the ENA and ENB jumpers on the L298N motor driver.

- Connect outer terminals of the potentiometer to VCC and GND, centre terminal to Analog pin A0 (Pin 26 in PICUNO)

- Connect the GND (-) pin to GND on board.

- Connect the VCC (+) pin to 5V on board.

- Connect the Signal (S) pin to GPIO 6.

SCHEMATIC:

L298N Motor Driver:

OUT2 & OUT2 → Outputs for the DC Motor.

12V → positive terminal (+) of 4xAA battery pack.

GND → negative terminal (-) of 4xAA battery pack → GND on PICUNO.

IN1 (Left Motor) → GPIO 8

IN2 (Left Motor) → GPIO 9

ENA (Left Motor speed) → GPIO 10

IN3 (Right Motor) → GPIO 11

IN4 (Right Motor) → GPIO 12

ENB (Right Motor) → GPIO 13

10kΩ Potentiometer:

Outer Terminals → VCC, GND

Centre Terminal → A0 (GPIO 26)

Light Blocking sensor:

GND / (-) → GND

VCC / (+) → 5V

Signal / (S) → GPIO 6

CODE -- C:

countPulse() function - This is the Interrupt Service Routine (ISR). It's a special, high-priority function that the microcontroller pauses its main loop() to run immediately whenever the sensor detects a pulse. Its only job is to increment the pulseCount.

attachInterrupt(...) - It tells the PICUNO to constantly monitor the SENSOR_PIN and to automatically run the countPulse() function every time it detects a FALLING edge (the signal going from high to low).

if (millis() - lastTime >= 1000) - The millis() function returns the number of milliseconds since the board started. This line checks if one second has passed without using a delay() command, which would freeze the program and cause pulses to be missed.

detachInterrupt() / attachInterrupt() - Before reading and resetting pulseCount, the interrupt is temporarily detached. This ensures the ISR can't change the value while the main loop is in the middle of a calculation. After the calculation, the interrupt is re-attached to resume counting.

attachInterrupt(...) - It tells the PICUNO to constantly monitor the SENSOR_PIN and to automatically run the countPulse() function every time it detects a FALLING edge (the signal going from high to low).

if (millis() - lastTime >= 1000) - The millis() function returns the number of milliseconds since the board started. This line checks if one second has passed without using a delay() command, which would freeze the program and cause pulses to be missed.

detachInterrupt() / attachInterrupt() - Before reading and resetting pulseCount, the interrupt is temporarily detached. This ensures the ISR can't change the value while the main loop is in the middle of a calculation. After the calculation, the interrupt is re-attached to resume counting.

CODE -- PYTHON:

count_pulse(pin) function - This is the Interrupt Service Routine (ISR). It's a special, high-priority function that runs automatically the instant a pulse is detected by the sensor pin. The global pulse_count line is essential, allowing this function to modify the main pulse_count variable.

sensor_pin.irq(...) - This line sets up the hardware interrupt. It tells the PicUNO to monitor the sensor_pin and, when it detects a FALLING edge (the signal going from high to low as a slot passes), to immediately run the count_pulse function.

if time.ticks_diff(...) >= 1000: - This is a non-blocking timer. It checks if at least one second has passed since the last calculation without using time.sleep(), which would freeze the program.

machine.disable_irq() / machine.enable_irq() - This block temporarily "pauses" all interrupts just long enough to safely copy the pulse_count value and then reset it to zero.

sensor_pin.irq(...) - This line sets up the hardware interrupt. It tells the PicUNO to monitor the sensor_pin and, when it detects a FALLING edge (the signal going from high to low as a slot passes), to immediately run the count_pulse function.

if time.ticks_diff(...) >= 1000: - This is a non-blocking timer. It checks if at least one second has passed since the last calculation without using time.sleep(), which would freeze the program.

machine.disable_irq() / machine.enable_irq() - This block temporarily "pauses" all interrupts just long enough to safely copy the pulse_count value and then reset it to zero.